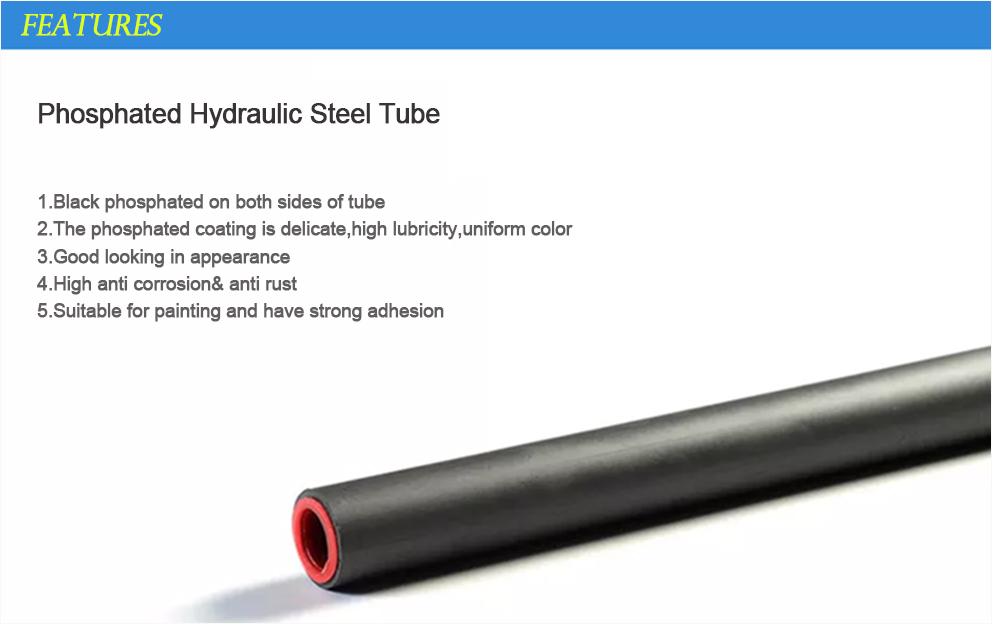

Cold Drawn/Rolled Black Phosphated Hydraulic Steel Tube with High Precision

Brief Introduction

The phosphated steel pipe for hydraulic pressure produced according to DIN 2391 or en10305 has a black and bright color, uniform color and good rust prevention function. Phosphated steel pipes are widely used in hydraulic systems, construction machinery and construction vehicles. It is the main export product of our company.

Phosphated hydraulic Seamless Steel Tube Advantages

- Outside and inside are both phosphated

- Good surface

- Good performance in Anti Rust and corrosion

- Widely used in Hydraulic Systerm

Technical Parameters

| Grade | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Standard | DIN2391 DIN1630 EN10305 DIN2445 JIS G3445 SAE J524 |

| Delivery Conditon | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| SIze | OD4 to 219mm Thickness 0.5-35mm, Length: Accroding to request |

| Tolerance | Outer Diameter: According to Standard |

| Thickness: According to Standard | |

| Finish | Phosphated Coating |

| Oil dipped | |

| Application | Hydraulic System;Car/bus;construction vehicle |

| Delivery time | A.7 days if this goods is stock goods. |

| B.20 days if this goods will be produced after order |

Delivery Condition

| Designation | Symbol | Description |

| Cold finished (hard) | BK(+C) | Tubes do not undergo heat treatment following the final cold forming and, thus, have a rather high resistance to deformation |

| Cold finished (Soft) | BKW (+LC) |

The final heat treatment is followed by cold drawing involving limited deformation. Appropriate further processing allows a certain degree of cold forming (e.g. bending, expanding) |

| Cold finished and stress-relieved | BKS(+SR) | Heat treatment is applied following the last cold forming process. Subject to appropriate processing conditions, the increase in the residual stresses involved enables both forming and machining to a certain degree. |

| Annealed | GBK(+A) | The last Cold forming process is followed by annealing in a controlled atmosphere. |

| Normalized | NBK(+N) | The last cold forming process is followed by annealing above the upper transformation point in a controlled atmosphere. |

Certificates: According to EN 10204 3.1

Inspection Items:

Tensile stength, Yield stength, Elongation, Flattenging, Flaring;

Chemical analysis

Eddy Current Test 100%, Size and surface checking 100%

Other test item can be arranged by A Third Party as per request