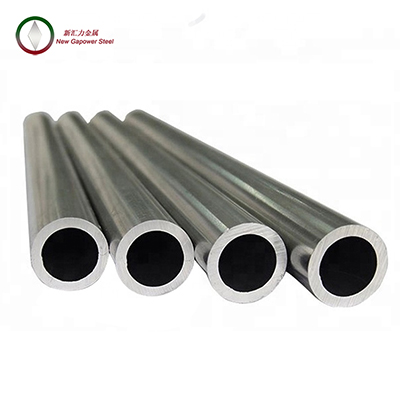

OEM/ODM Manufacturer Precision API 5L ASTM A106 Sch Xs Sch40 Sch80 Sch 160 Seamless Carbon Steel Pipe St37ms CS Seamless Carbon Steel Seamless Steel Pipe and Tube

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with OEM/ODM Manufacturer Precision API 5L ASTM A106 Sch Xs Sch40 Sch80 Sch 160 Seamless Carbon Steel Pipe St37ms CS Seamless Carbon Steel Seamless Steel Pipe and Tube, We welcome new and old customers to contact us by phone or send us inquiries by mail for future business relationships and achieving mutual success.

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with China Carbon Steel Tube and Carbon Steel Pipe, With strong technical strength and advanced production equipment, and SMS people purposefully , qualified, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

Brief Introduction

ST37.4 ST44.4 ST52.4 Steel Grade Seamless Steel Tube for dynamic Loads Normal Pressures 100 to 400 bar is our company mainly product. It is widly used in heavy duty truck, military industry, railway locomotive,engine filed and the gas line in special vehicle.They could meet the requiremnts because of high precison of Out diameter and Inner diameter. Also its anti corrosion performance.

Technical Characteristics

Standard: DIN 1630 DIN2445

Grade: ST37.4 ST44.4 ST52.4

Heat Treament: NBK(+N) normalized, BK, GBK,

Surface Treament: Army green passivated, Sliver Galvanized, Black Phosphated,Black paint,

Straightness: 1mm/1000mm

Dimension Telorance: According to DIN1630 DIN2445 Standard

Feature

High precison, smooth surface

Strong anti rust/corrosion property

No any corrosion after 220 hours’ Sale Spray Test

Delivery Conditions

The tubes can be produced in the following delivery conditions:

BK (+C) Cold finished/hard (cold finished as drawn).

No heat treatment after the last cold forming process.

BKW (+LC) Cold finished/soft (lightly cold worked)

After the last heat treatment there is a light finishing pass (cold drawing).

BKS (+SR) Cold finished/stress relieve annealed.

After the final cold forming process the tubes are stress relieve annealed.

GBK (+A) Annealed.

After the final cold forming process the tubes are annealed in a controlled atmosphere.

NBK (+N) Normalized. (Mainly focus on)

After the final cold forming process the tubes are annealed above the upper transformation point in a controlled atmosphere

Application