Stainless steel seamless pipes are steel pipes that are resistant to weak corrosive media such as air, steam, and water, and chemically corrosive media such as acids, alkalis, and salts, also known as stainless acid-resistant steel pipes.

The corrosion resistance of stainless steel seamless pipes depends on the alloying elements contained in the steel. Chromium is the basic element for the corrosion resistance of stainless steel. When the chromium content in the steel reaches about 12%, the chromium interacts with the oxygen in the corrosive medium to form a very thin oxide film (self-passivation film) on the surface of the steel. , Can prevent further corrosion of the steel matrix.

Stainless steel seamless pipe production steps: 1. Round steel preparation; 2. Heating; 3. Hot rolled piercing; 4. Cut the head; 5. Pickling; 6. Grinding; 7. Lubrication; 8. Cold rolling processing; 9. Degreasing; 10. Solution heat treatment; 11. Straightening; 12. Cut the tube; 13. Pickling; 14. Product testing.

The main stainless steel materials are: 201, 202, 209, 301, 304, 304L, 310, 321, 316 316L, 309S, 310S, 904L, 1Cr17, 1Cr13, 2Cr13, 3Cr13.

Product Description

| Grade |

201 202 304 304L 316 316L 310S 316 316L 321 409L 904L etc. |

| Standard |

ASTM A554, A249, A269 and A270,A312 |

| Diameter |

6mm–159mm |

| Length |

6m or as customers’request |

| Tolerance |

Outer Diameter:+/-0.2mm, |

| Thickness:+/-0.02nn,Length:+/-5mm |

| Finish |

Aid Pickling, Polishing, Brushing |

| 180G, 320G, 400G Satin/Hairline 400G, 500G, 600G or 800G Mirror finish |

| Application |

Decoration construction, upholstery, industry instrument |

| Delivery time |

A.7 days if this goods is stock goods. |

| B.20 days if this goods will be produced after order |

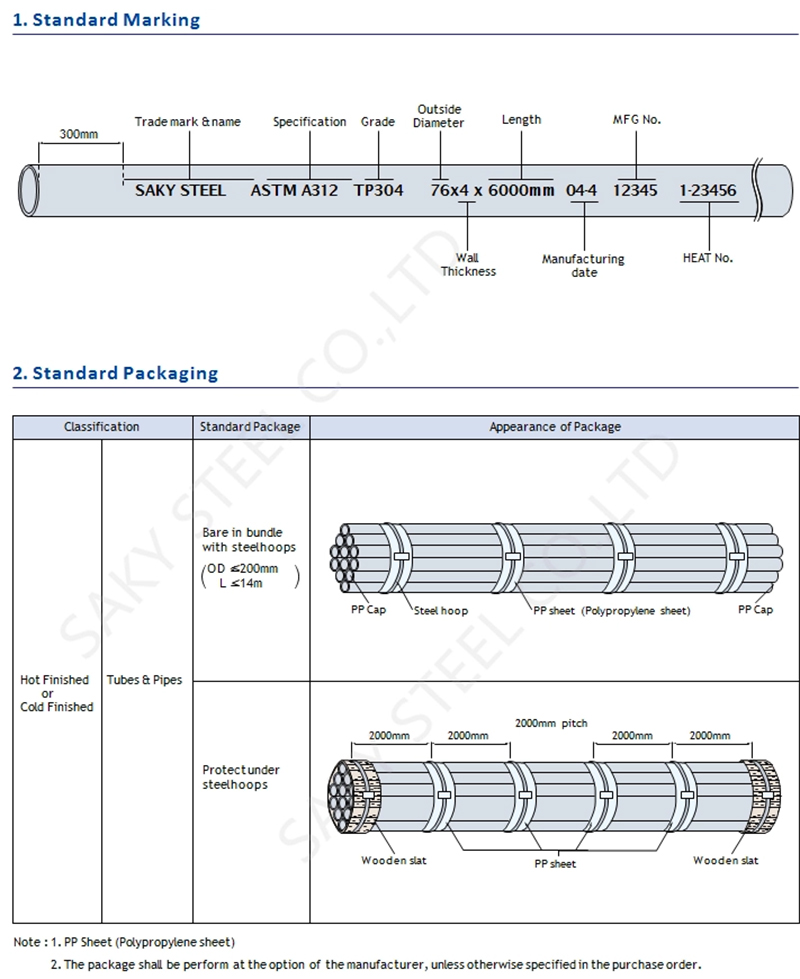

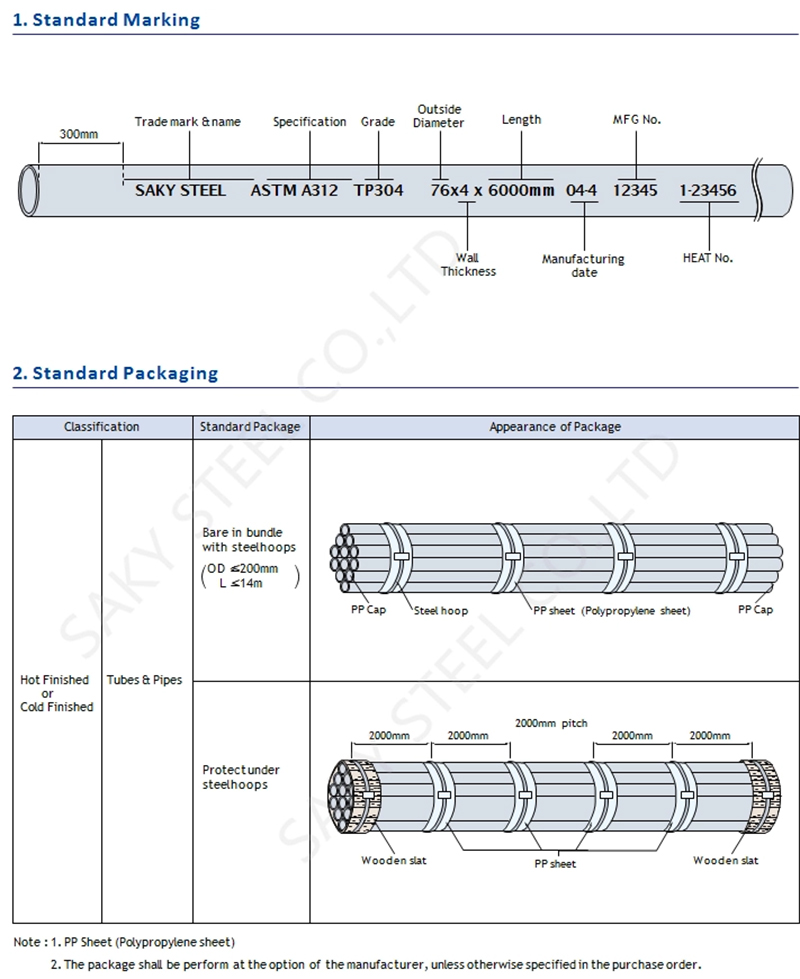

Normal Marking and Package

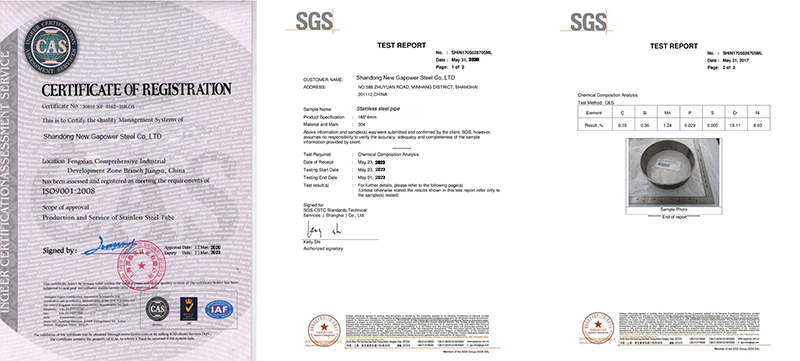

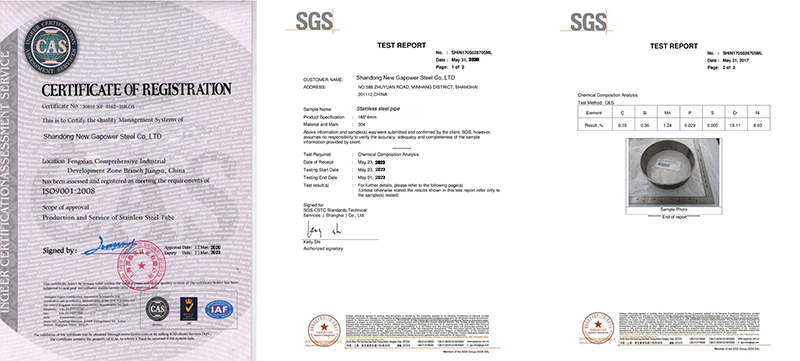

Products Inspection

Tests of Stainless Steel Seamless Pipe

1.Chemical Analysis (ASTM E345)

2.Mechanical Properties (Tension: ASTM E8)

3.Nondestructive Test

3.1:100% Hydrostatic Test

3.2:According to ASTM A450/A450M

Previous: Stainless Steel Coil

Next: 201/202/304/316 Stainless Steel Plate